27 Oct Top 3 Complex Cable Assemblies: Box Build, Panel Build, Terminal Assembly

A lot goes into building a custom cable assembly, and one of the first steps is knowing what kind you need. Find out the difference between panel build assemblies, box build assemblies, and terminal block assemblies so that you can start your project right.

Whether you’re designing a printed circuit board assembly (PCBA) or a medical cable assembly for an innovative application, a custom cable assembly can be a very complex build. The design process can become even more complicated if you don’t know which kind of assembly you need, so understanding what your options are is essential.

While no two projects are the same, there are three primary types of custom cable assemblies available: box builds, panel builds, and terminal block assemblies. In this post, we’ll define all three and look at the components used to build each, along with some industries where you might find them. That way, you can choose the custom cable assembly design that’s right for you.

NAI’s Unique Complex Cable Assembly Capabilities

Box builds, panel builds, and terminal block assemblies can require complicated designs and also be complicated to manufacture. One of NAI’s key value propositions is solving a difficult problem for a customer, and those problems run the gamut.

NAI is a trusted company when it comes to designs and builds of complex assemblies, with a perfect example being our recent case study for an international mining customer.

The NAI Competitive Advantage for Complex Cable Assembly Manufacturing

NAI has a competitive advantage with these types of interconnects. The smaller companies (think “ma and pa shops”) don’t have the capability to either make these or produce them in volume in a timely fashion. And larger companies might not accept the smaller volume orders that NAI can.

NAI also proves their worth by being capable of producing both high volume/low mix orders, as well as high mix/low volume orders. High mix refers to many different configurations and part numbers, each at lower volumes, whereas low mix refers to fewer part numbers, made in high volume.

When it comes to custom complex assemblies, no one pays attention to the details quite like NAI. From your idea to the final product, we are here to ensure that your complex cable assemblies are as custom as you need them to be.

1. Custom Box Build Assembly Options

Unlike a simple cable assembly, a custom box build assembly consists of all the components contained within the project — including the enclosure. Complete with all the electronic, mechanical, and hardware components that it takes to make an assembly function, a systems integration or box build incorporates all the pieces of your project into one and factors in the housing as well.

The box itself is one of the most critical parts of a build, as it protects delicate electromechanical components from potentially harmful environmental conditions.

Methods and Materials for Box Build Assembly Manufacturing

As an enclosure material, stainless steel sheet metal is most commonly used for box builds, as it can easily be machined to a custom design without compromising its structural integrity. Certain types of plastic can also be a good choice. Aside from the enclosure, other common box build components and materials include:

- Copper cable assemblies

- Fiber optic assemblies

- PCBs

- Processors

- Connectors

- Motors

- Thermal components (fans, heat sinks, etc.)

- Fasteners (brackets, ferrules, bushings, etc.)

- Much more

The vast number of components involved in production means that manufacturers must have not only the ability to source the right parts but also the expertise and facilities for end-to-end production of your build. That’s why it’s so important to find the right provider.

Benefits and Applications of Custom Cable Assemblies

One of the greatest benefits of using a box build as your custom cable assembly design is the all-in-one functionality that it provides. A box build assembly contains all the subsystems for your electromechanical design in one plug-and-play solution. That makes it ideal for industries like:

- Telecom and data

- Medical

- Industrial

- Robotics

- Automotive

- Much more

If your application requires a turnkey solution that’s ready to integrate with the rest of the subsystems for your project, a box build assembly may be the way to go.

2. Find Custom Panel Build Assembly Options

There’s plenty of overlap between the two, but a panel build differs slightly from a box build in that it’s usually used to manufacture control panels, switches, or other control platforms. Also, since there may be more interaction with the interface of a control panel than with an internally housed box build assembly, aesthetics, surface finish, and user-friendliness may play more of a role.

Methods and Materials for Panel Build Assemblies

The need for a user-friendly external surface area makes either plastic or metal a good choice for a panel build enclosure. These can be provided with a smooth finish, in custom colors, and with imprinted brand graphics. Other features of a panel build assembly include subsystems common to the control panel industry, like:

- Logic processors

- Sensors

- Switches

- Lights

- I/Os

- Power supplies

- Much more

Panel builds and box builds share other components too, but where users interact with them — especially within the controller/control panel industry — a panel build is likely the system at play.

Benefits and Applications of a Panel Build Assembly

Panel build assemblies offer many of the same advantages that box builds do, with the exception that the number of switches and outward-facing interface devices makes them ideal for control panel configurations. Some panel builds include:

- PLC boxes

- SCADA boards

- Thermostat controllers

- Remote controls

As with box builds, a panel build assembly is an end-to-end product, so manufacturing one according to spec takes knowledge and resources in a host of engineering and manufacturing subdisciplines.

3. Get Terminal Block Assembly Options

Both box builds and panel builds are more comprehensive than a terminal block assembly. A terminal block assembly consists of a cable assembly preassembled to a terminal block for use in larger systems. Terminal block assemblies are a key component of many larger projects and are often used in the telecommunications industry to simplify and manage connections.

Methods and Materials for Terminal Box Assemblies

To manufacture a terminal block assembly, the cable type, fasteners, and interconnects must be specified. That includes:

- Copper cables

- Fiber-optic cables

- Hybrid cables

- Ferrules

- Pins

- Plugs

- Strain reducers

- Jackets

- Sheathes

- Custom terminal blocks

Plastics are often the material of choice for many terminal components due to their low electrical conductivity, and it’s also important to know what your cable will be connecting to so that you can utilize the proper size and consider other specifications.

Terminal Box Assembly Benefits and Applications

One of the advantages of terminal block assemblies is their versatility. They can be used either as stand-alone products or as components within a larger subsystem — like a box build or panel build.

Quality Cable: The Common Denominator of Custom Cable Assemblies

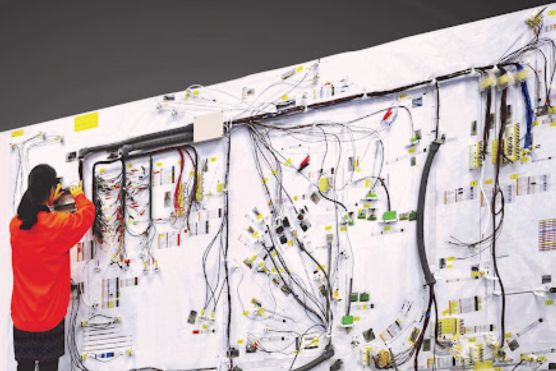

Last, but not least, is the cable assembly that is used to interconnect components in any of the above project types. While box and panel builds can be very complex themselves, many cable assemblies and harnesses required for these projects can be very complex themselves…and difficult to manufacture correctly. As an example, the harness shown in the main photo above had over 900 terminations.

NAI: The Top Global Custom Cable Assembly Manufacturer

NAI has the capability to design and manufacture custom cable assemblies, including box builds, panel builds, and terminal block assemblies. These multi-faceted interconnect solutions can be a huge challenge for some companies to manufacture. So, when it comes to these top three complex assembly project types, you should choose NAI as your manufacturing partner.

Not only are we industry leaders due to our engineering and manufacturing expertise and facilities, but our international sourcing network also enables us to obtain the custom components you need and always build your cable assembly according to spec.

Contact us today and see how we can help with your complex interconnect project!