14 Aug NAI Offers Personalized Cable Engineering Services for Custom Cable Assemblies

As the technology landscape evolves at an unprecedented pace, so do the current trends that impact the custom cable assembly industry. As the demand for top-tier custom cable solutions has surged exponentially, NAI continues to offer comprehensive personalized cable engineering services.

The core aspect for our continued success over the years? Making sure that our customer engagement model not only revolves around meeting our clients’ distinct requirements, but directly involving them in the cable assembly process to whatever degree they desire.

One of the things that sets NAI apart is a customer-centric engagement model. By engaging in close collaboration and understanding the unique demands of each project, NAI ensures that its engineering services are precisely aligned with the customer’s goals, industry standards, and environmental considerations while ensuring a meaningful relationship is developed to provide the utmost customer service and a reliable product outcome.

With the capital, experience, global footprint, and expert staff, NAI has developed a profound understanding of custom cable design and manufacturing. Read on to see that one of the benefits of working with an industry leader is how closely they work with customers to translate their intricate specifications into meticulously crafted custom cable assemblies and cable harnesses through NAI’s personalized cable engineering services.

Why Customers Should Have a Say in Their Custom Cable Assemblies and Wiring Harnesses

At NAI Group, we understand customers are deeply versed and knowledgeable about the cable assembly products they use and can provide valuable insights into the design and development stages of custom cable assemblies.

At NAI Group, we understand customers are deeply versed and knowledgeable about the cable assembly products they use and can provide valuable insights into the design and development stages of custom cable assemblies.

By working alongside customers, and incorporating their feedback and input into the process, NAI can ensure the final cable assembly product is tailored to each client’s precise needs and requirements.

This collaboration-first approach to development ensures higher-quality results and fosters stronger relations between the client and the cable assembly manufacturer, prompting long-term success and cooperation. This is why knowing how to choose an interconnect manufacturer based on the services they provide is incredibly important.

Moreover, active client engagement is one of the strongest stimulants for innovations. Working directly with our clients enables us to craft interconnect solutions that focus on communication and understanding, plus direct service of the needs and aspirations of your custom cable assembly project.

NAI’s 3 Customer Engagement Models

To promote and personalize the custom cable assembly process, NAI offers three core customer engagement models that cater to different levels of independence and involvement, depending on customer experience and project complexity.

To promote and personalize the custom cable assembly process, NAI offers three core customer engagement models that cater to different levels of independence and involvement, depending on customer experience and project complexity.

Each of the following design models provides unique benefits, ranging from reduced lead times and cost-savings to tailored solutions.

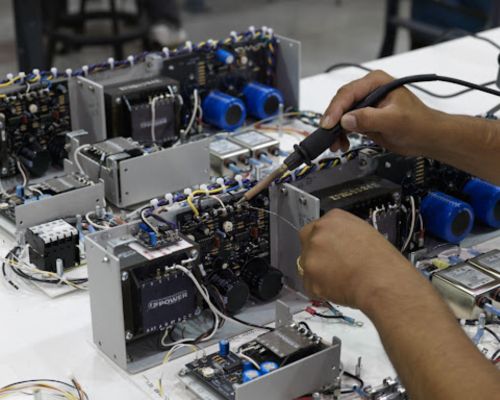

1. Build-To-Print: This approach is suitable for clients seeking a simplified and straightforward cable assembly solution. Our New Product Introduction team of production planning experts will take your build-to-print order and prepare plans for each detailed production stage required, including testing. The customer provides prints and a BOM, and NAI manufactures the assembly.

2. Design Assist: Clients looking to acquire cable assembly solutions that meet unique requirements and specifications can tap our expert engineering teams to assist in the final development of their interconnect project. Here, the customer provides 50% or more of the design specification, while NAI provides design documentation such as prints or BOM and then manufactures the assembly.

3. Full-Service Custom Design: In many cases, customers choose to have our engineering team produce a design concept that solves a problem, or they provide less than 50% of the design specification. NAI designs and develops a custom solution, generates the design documentation, and manufactures the finished assembly.

If you have specific components in mind or specified in your design, NAI engineers can recommend alternatives to help meet delivery needs and reduce your costs.

We understand that it can be hard to trust a manufacturer to take the utmost care and precision with your custom cable assemblies. So don’t just take our word for it, look at our results.

As explained in our recent blog, NAI Group designed and manufactured custom cable harnesses and box builds for a customer in the mining industry. This case study showcases NAI Group’s expertise in providing customized connectivity solutions, even ones that encompass challenging environments and global distance.

Check out our other case studies to confirm that NAI has the ability to provide the high-quality interconnect solution you deserve with the custom specifications you need.

Other Custom Benefits for NAI Customers

While our engineering engagement model is for our customers, NAI Group’s commitment to providing state-of-the-art and superior cable assembly engineering services goes beyond offering basic customer engagement models.

While our engineering engagement model is for our customers, NAI Group’s commitment to providing state-of-the-art and superior cable assembly engineering services goes beyond offering basic customer engagement models.

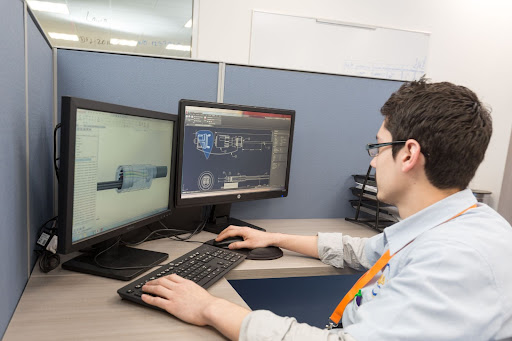

State-of-the-Art Design and Engineering Facilities

Our advanced design and engineering facilities are equipped with the latest equipment and technology, and staffed by a team of experienced cable assembly engineers and professionals. This ensures every custom cable assembly is designed and produced to the highest quality standards in your region and industry.

The NAI Solutions Center in Troy, Michigan, is where our expert engineers and designers collaborate on creating the right connectivity solutions for your specific application. However, we have local and consulting engineers in China, Southeast Asia, and Mexico as well.

Client Access to the Best Tools and Processes

By leveraging some of our industry’s latest tools and cable assembly manufacturing processes, NAI can streamline the design and production of custom cable assembly designs. This allows us to offer faster turnaround times, superior performance, and increased efficiency.

As one of the leading interconnect manufacturers in the country, our engineers offer a range of advice on material substitutes and manufacturing process innovations to help design and create new products from scratch.

Global Supply Chain Benefits

Our global supply chain encompasses a wide variety of cables, connectors, and other components, allowing you the opportunity to customize any project, regardless of size or location with NAI’s advanced manufacturing facilities located strategically around the globe.

We can deliver custom cable assemblies to customers quickly and efficiently, reducing lead times and costs in the process.

Choose NAI for Superior Cable Engineering Services

NAI Group’s personalized cable assembly engineering services, combined with our cutting-edge facilities and global supply chain make us the ideal partner for custom cable assembly projects in a wide range of industries and locations. We’re committed to involving customers in the design process, offering them a variety of engagement models, and ensuring every cable assembly is tailored to meet their specific needs and requirements.

At NAI, we firmly believe you should have a say in all parts of the cable assembly manufacturing process—from the early design and brainstorming stages to quality standards and the production process. When it comes to engineering custom cable assembly solutions, we offer comprehensive programs that are adaptable, efficient, and client-focused. Contact us to have our NAI experts answer all your questions and help you find the best solution for your connectivity project.