-

Problem-Solving Case Studies

A large global manufacturer of industrial robots has been experiencing robust growth and demand for its products. Its legacy interconnect supply base was unable to provide the capacity, ramp-up speed, and production volume that the manufacturer required to meet its increasing demand. They turned to NAI to produce a variety of rugged cable assemblies and harnesses to meet their demanding deadlines.

Read the Problem / Solution Story

Download the Problem / Solution Story

NAI Creates Dual Capacity to Offset Customer’s Delivery Issues During the Pandemic

NAI’s global footprint provides a definite advantage for interconnect customers looking for extra insurance and to mitigate risk, so they can remain focused on providing continuity of supply to their customers. Read about how NAI helped one customer by building dual capacity in a different global location to help that customer maintain its product deliveries during the pandemic.

Read the Problem / Solution Story

Download the Problem / Solution Story

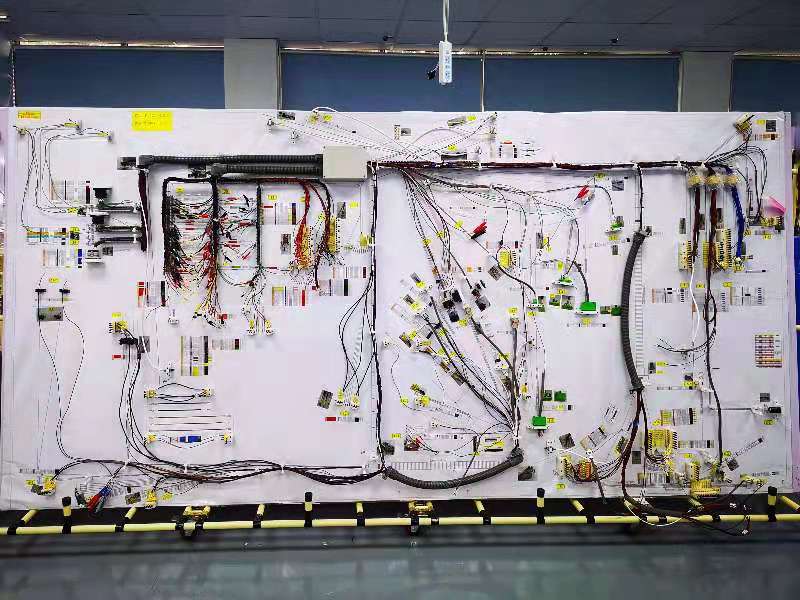

Initial production line dedicated to a customer part-specific operation in Hermosillo, Mexico.

Part of the same custom interconnect production line in Hermosillo, Mexico.

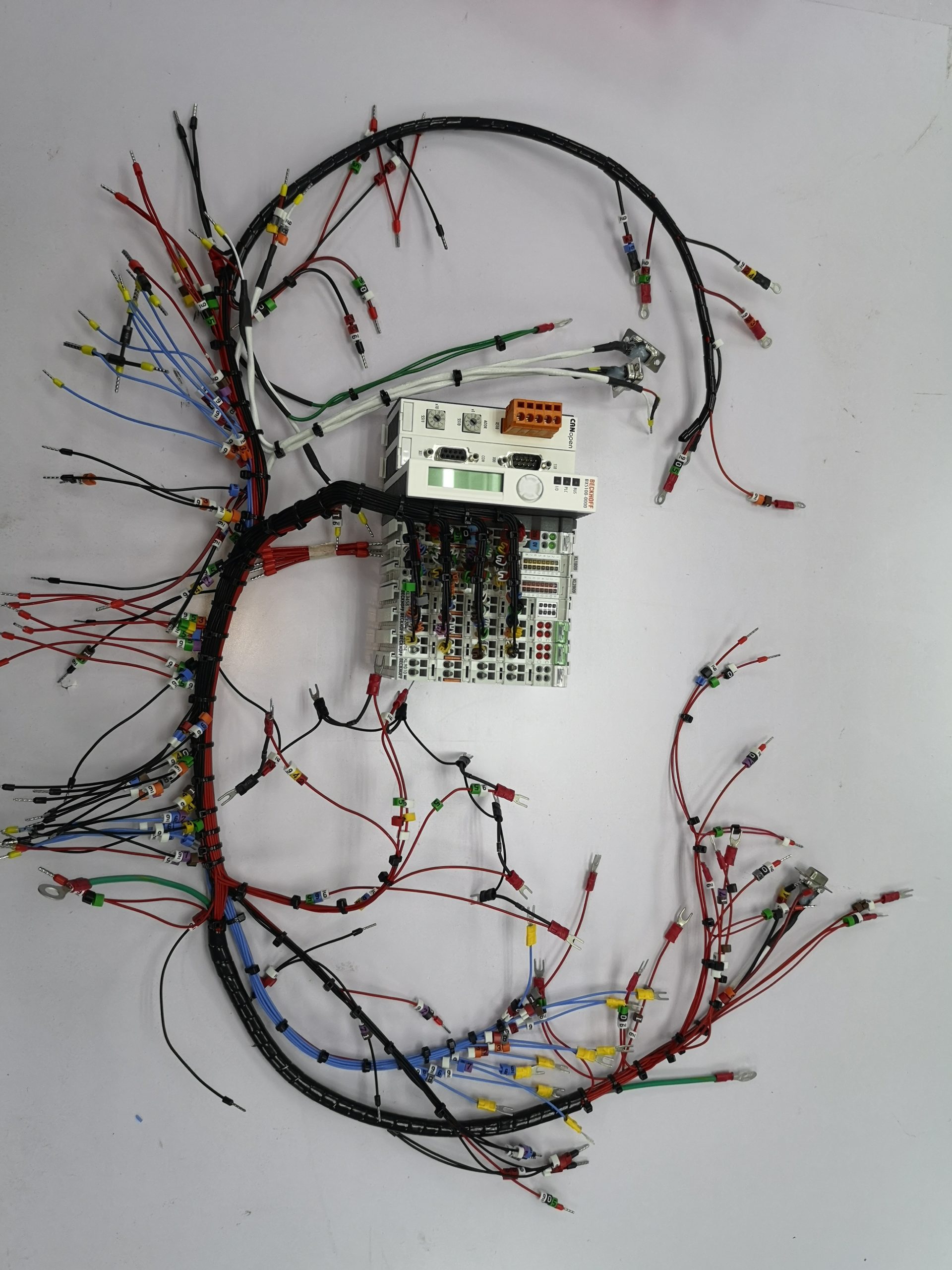

This new part-specific operation established in Suzhou, China mirrored the Hermosillo operation to create dual capacity and mitigate regional pandemic risk.

Assembling a cable harness for this dual capacity production operation in Suzhou, China.

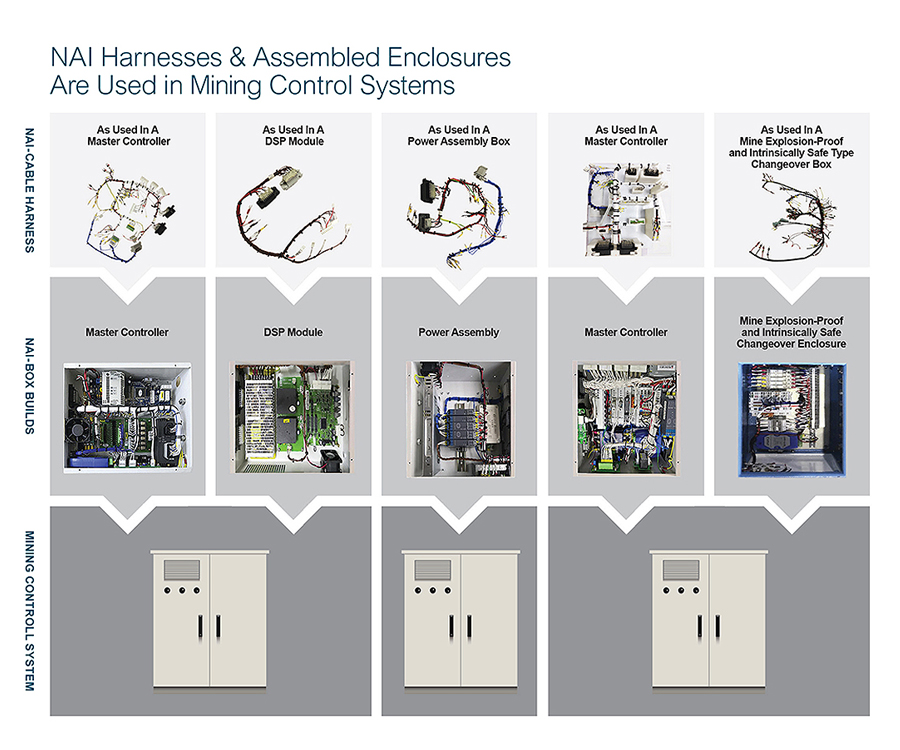

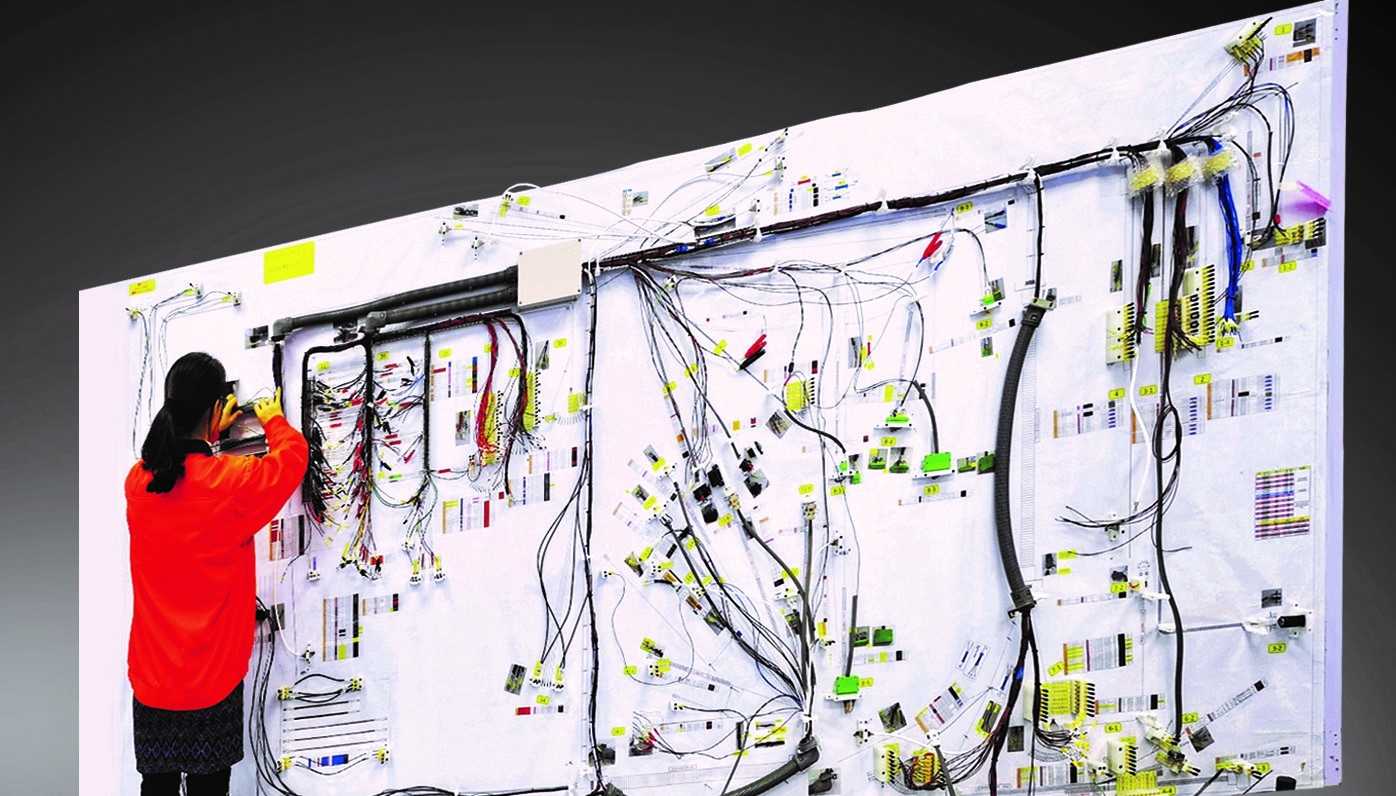

One of the large harness assemblies used for the mining controls project.

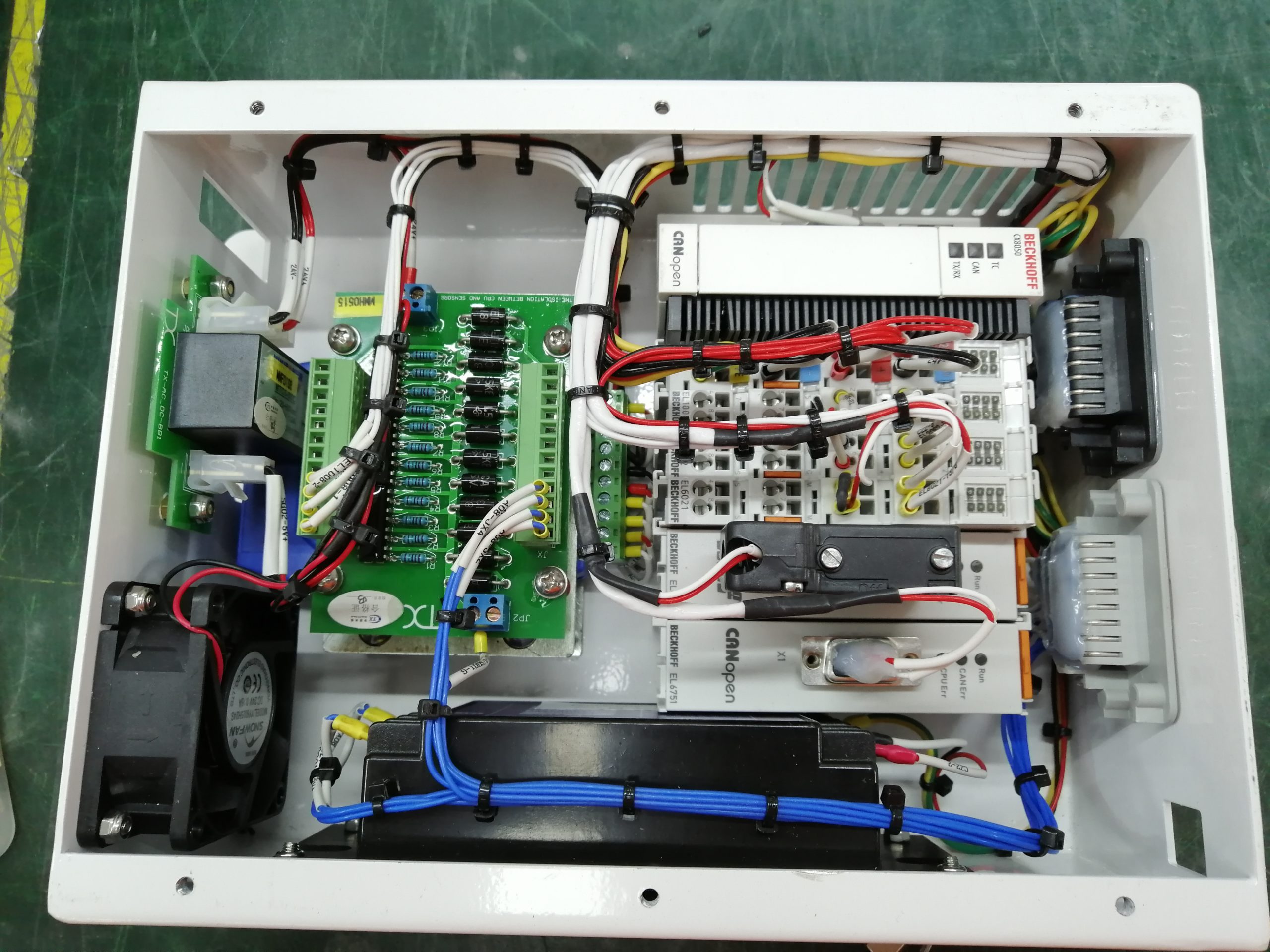

One of the smaller harnesses used in the box builds for this project.

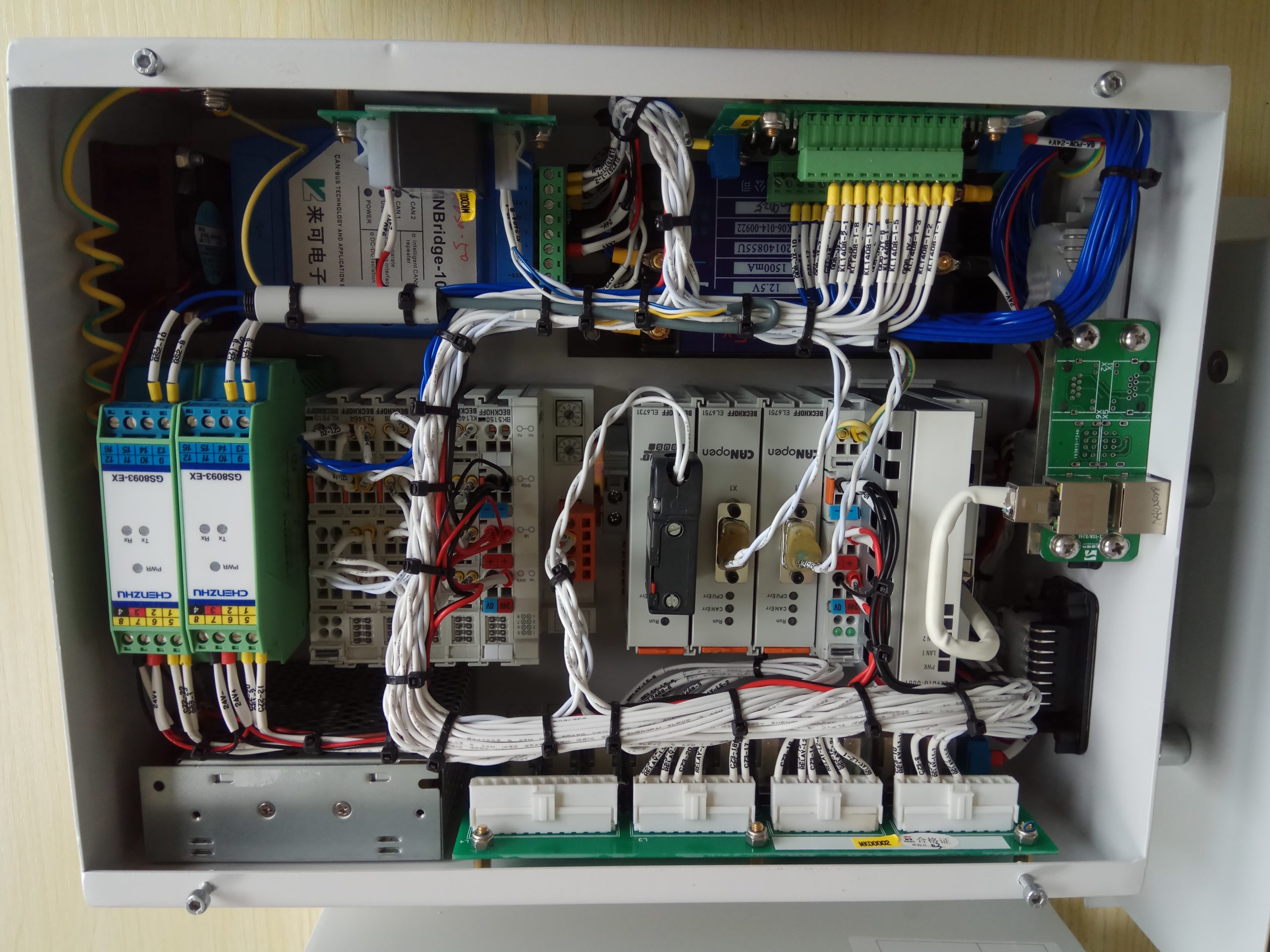

One of the many box builds used in the mining control cabinets.

Another sample box build used in the mining control cabinets.

NAI Customer Achieves Greater Efficiency and Reduces Total Costs by Outsourcing Harness Assemblies and Box Builds to NAI

A mining control equipment manufacturer could not build harnesses and assemble enclosures internally as well as an outside interconnect supplier with experience in making rugged assemblies for hazardous environments. They decided to outsource to NAI to achieve better quality, reduce lead times and obtain other benefits. Most importantly, this supply arrangement allowed the customer to focus on their core business, and use NAI’s expertise in design and manufacturing, as well as leverage their global procurement resources, to produce the harnesses and box builds needed.

Read the Problem / Solution Story

Download the Problem / Solution Story